I.T.S. provides a wide range of automation services, including complete facility communication and control, custom machine design and ABB Robotics integration.

Through the use of programmable logic controllers, I.T.S. provides complete plant communication all controlled from any accessible touchscreen to a laptop. Custom machines can be designed to handle a wide range of processes including: manufacturing, machine tending, and material handling. Our value provider program with ABB robotics also offers more opportunity for your business to advance.

Throughout the stages of concept, design, assembly, and testing, the experienced engineering team works closely with the customer to ensure a seamless end product; while using the industry leader in 3D modeling software, Solidworks. 3D modeling offers robust, rapid design capabilities and will ensure the customer is fully aware of the machine’s functional ability as the design progresses.

I.T.S. provides complete service to industry under one roof!

Our capabilities include:

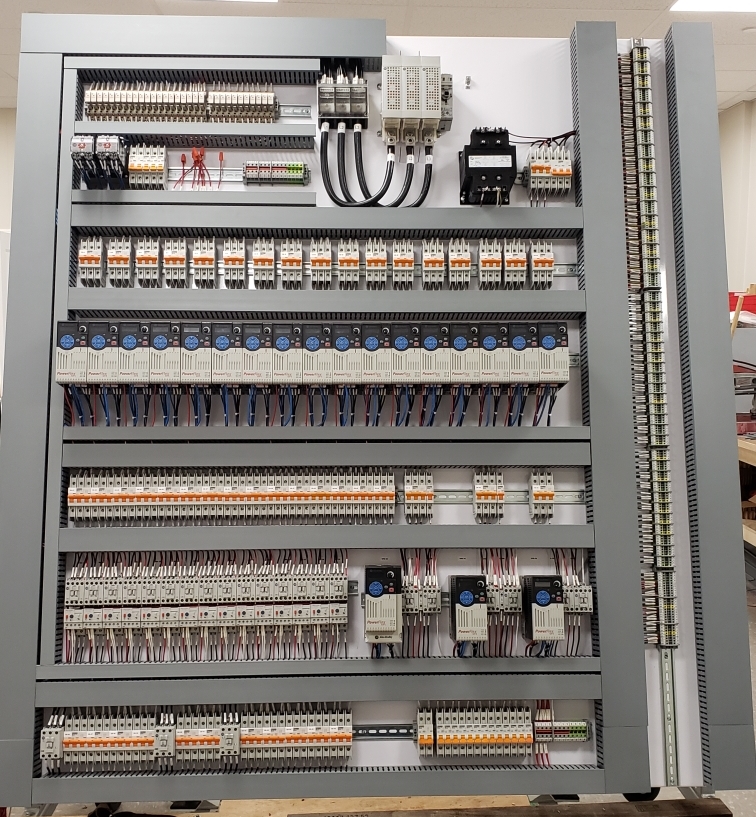

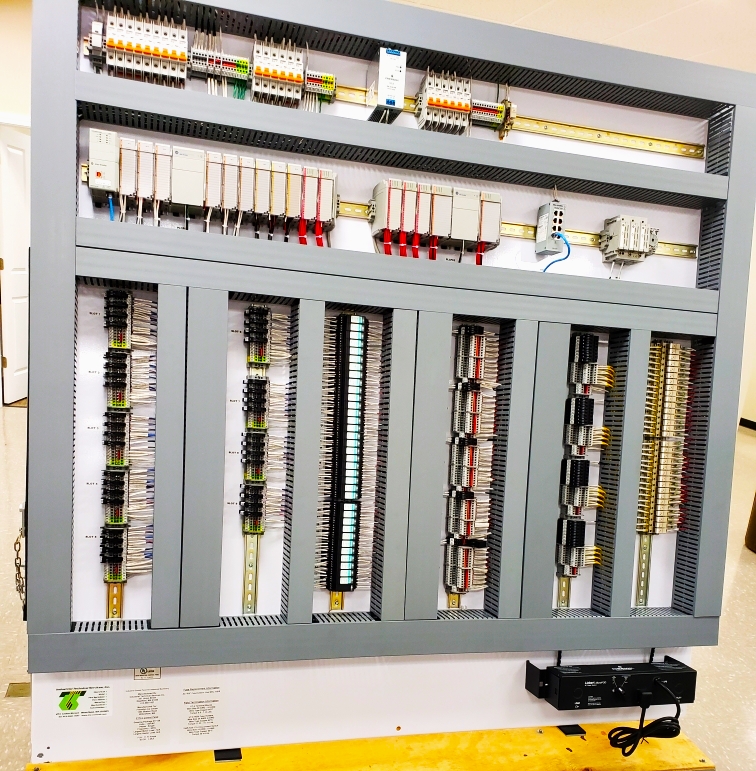

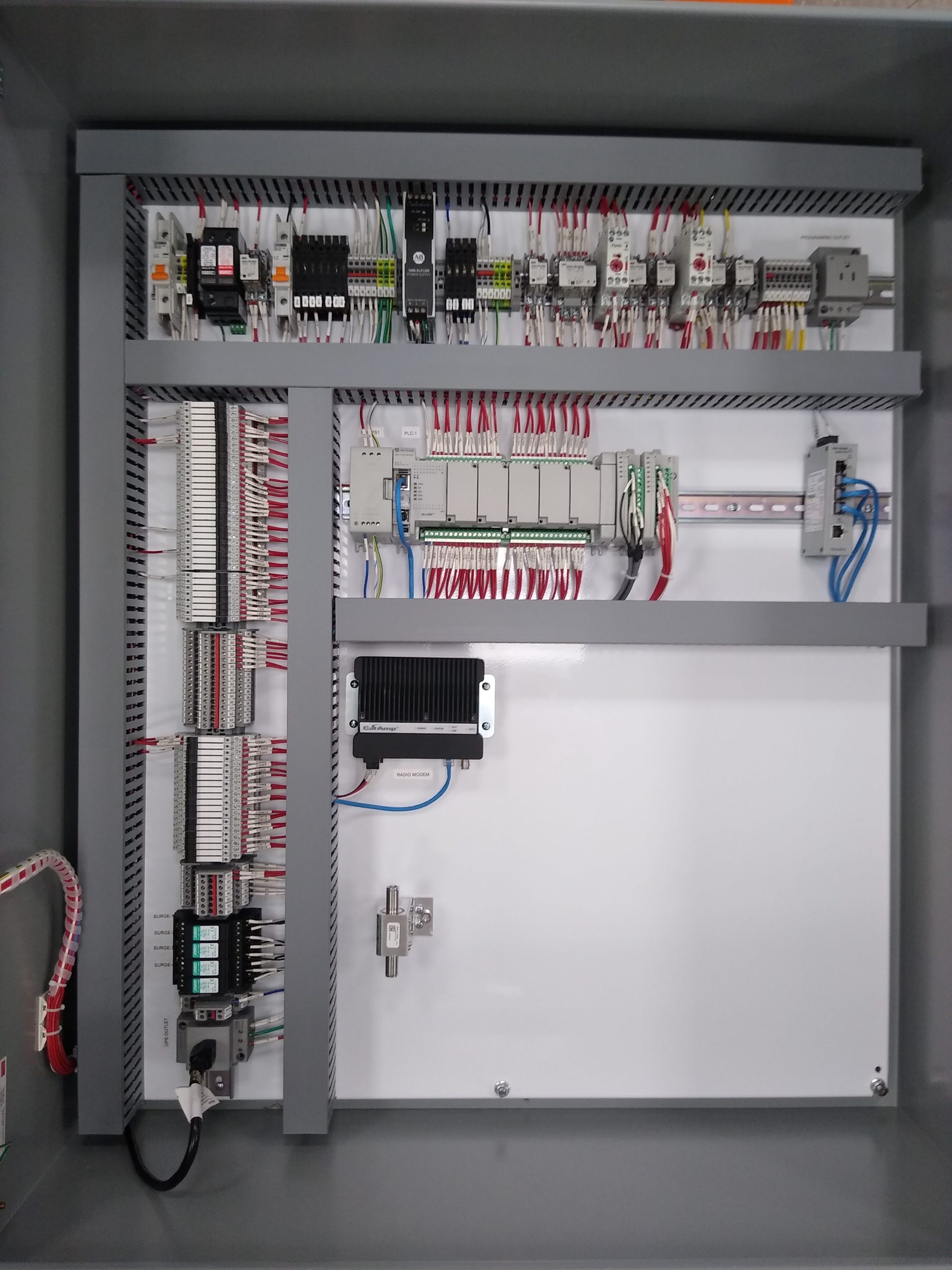

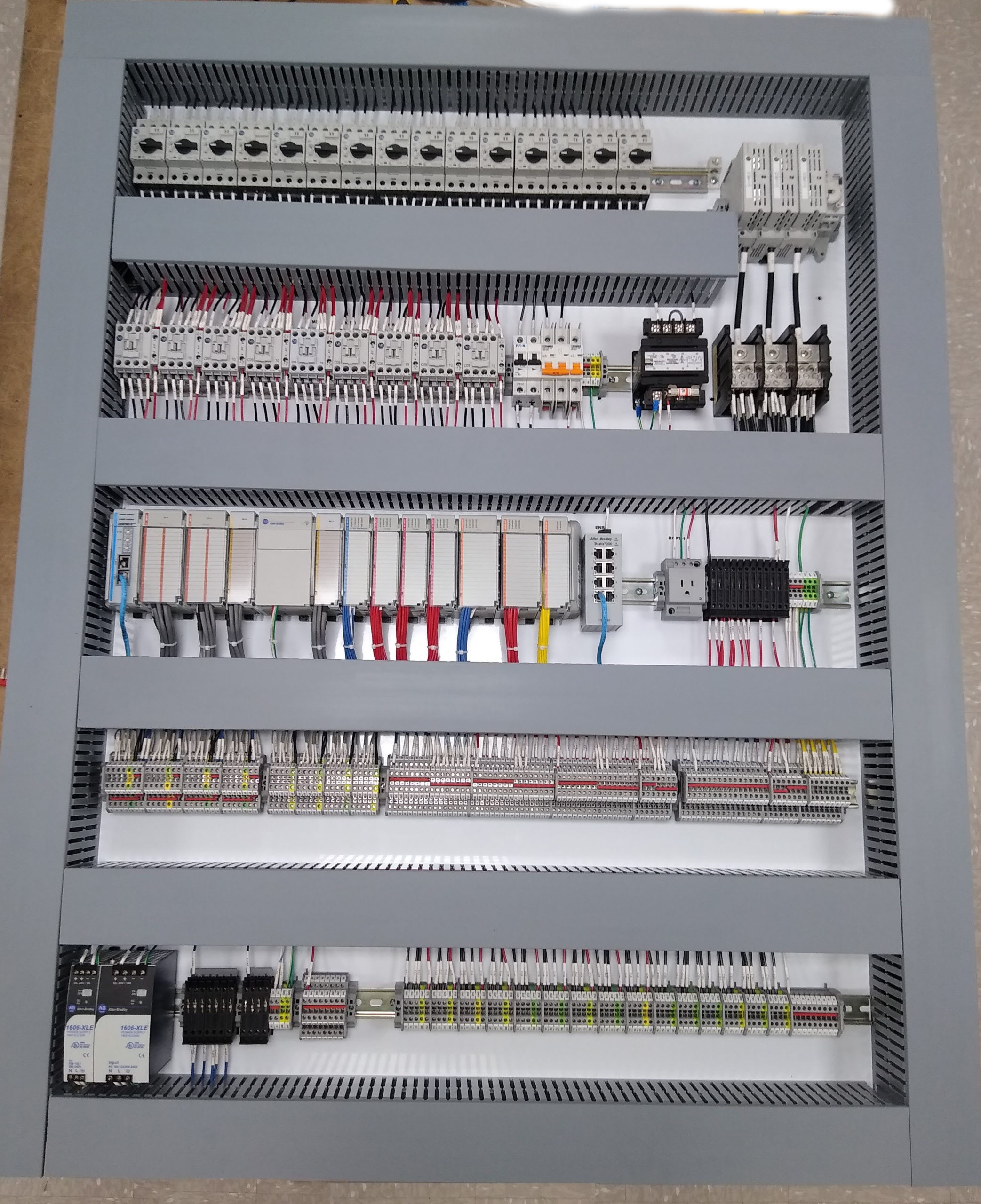

- UL 508A Certified Industrial Certified Panel Shop

- PLC, HMI, and SCADA Certified Programming

- Process instrumentation

- UHF and VHF frequencies

- Radio Telemetry

- ABB Robotics Value Provider

- Complete Machine Fabrication shop

- Engineering Services (Machine Design)

- And much more!

UL 508A Certified Industrial Control Panel Manufacturing Shop

When you work with us, you can be certain you’re getting a full service automation team. We have our own control panel manufacturing shop where we specialize in custom manufacturing, installation, design and fabrication of any type of control panel.

I.T.S. offers a one-stop shop with our panel shop and other automation related services!

PLC and HMI Programming + SCADA Systems

Our automation specialists specialize in PLC and HMI programming, along with various brands of equipment including: Allen Bradley, AutomationDirect, C-Moore, EZ-Touch, Maple Systems, General Electric, Siemens and Modicon. Our wide range of experience allows us to provide automation services for all types of systems!

Specializing in SCADA systems allows our automation professionals to provide our customers with real-time data and monitor your equipment. A SCADA system allows you to be notified of any issues immediately and in turn, allows us to respond quickly. SCADA systems we install and maintain include: packages from National Instruments Lookout, Wonderware, FactoryTalk, and more

Process Instrumentation + Radio Telemetry

As a full service automation team, we provide onsite or offsite calibration services on your systems. We are licensed in UHF and VHF frequencies and specialize in radio telemetry services. Largely used in water and waste-water applications. We also have extensive experience working with Teledesign Systems, Simrex and ProSoft.

For an experienced industrial or commercial automation services team that you can rely on to provide you with cutting edge technology, I.T.S. is the match for you. We can truly provide you with an array of top of the line robotic and automation services despite the system you’re working with!